CHAIN SLINGS

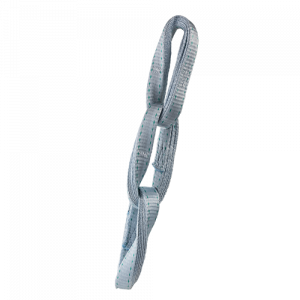

Chain slings provide the link between the lifting equipment and the load to be lifted. Used by professionals, chain slings are known for their unbeatable price/quality ratio. Chain slings can be made of high-strength galvanised steel or stainless steel for use in wet and corrosive environments.

Just like wire rope slings, we carefully manufacture chain slings in our lifting and handling workshops in France according to your diameter, length and number of strands of your choice. Chain slings are differentiated by their steel grade corresponding to their breaking strength, so there are grade 80, grade 100 and grade 120 slings.

The 80 grade chain sling is the most commonly used and least expensive. If you want slings with maximum lifting capacity, grade 100 and 120 slings are the best choice. Grade 120 slings have smaller diameter links and weigh 30% less than a grade 80 sling.

How to choose a chain sling?

To choose the right chain sling for your operation, you need to :

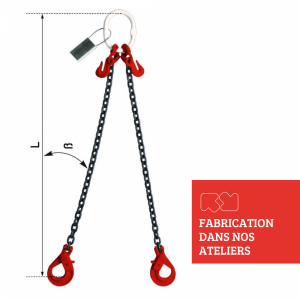

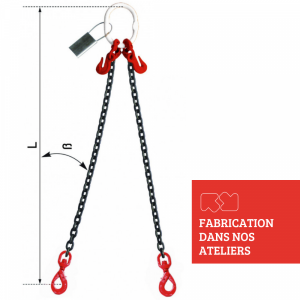

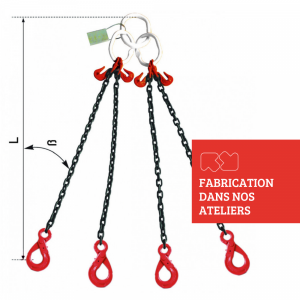

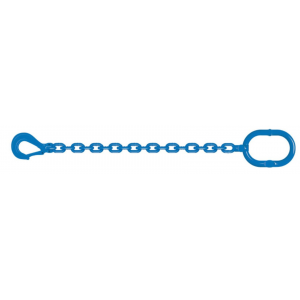

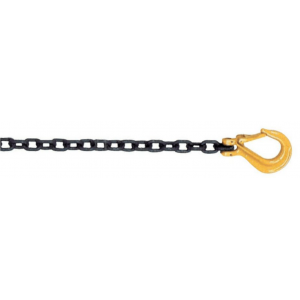

Know the type of chain sling you want according to its attachment points: 1 strand, 2 strands, 3 or 4 strands.

Know the maximum working load required to lift the load

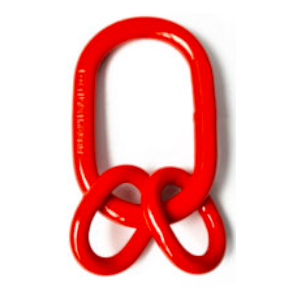

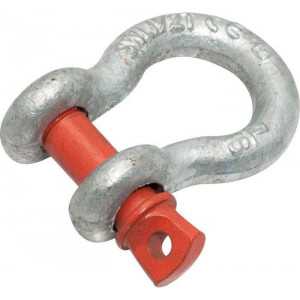

Choose the type of hook or chain slings accessories to be fitted to the chain sling

Know the total working length of the lifting sling

You can also choose to add a shortening hook to your chain slings which allows you to adapt the length of the sling to your needs.

Our chain slings all have an identification plate with the CMU, the CE mark and the manufacturer's mark.

To avoid any risk of accident, please check your chain slings regularly by monitoring the condition of the links. If a link is deformed, cracked or has an elongation of more than 5%, we strongly advise you not to use your sling. We are able to inspect your chain slings in our workshop, please contact our inspection and repair department.

If you have any further questions about chain slings, please contact our customer service department, they will answer all your questions.

CHAIN SLINGS

CHAIN SLINGS  CHAIN SLINGS ACCESSORIES

CHAIN SLINGS ACCESSORIES  CHAINES

CHAINES